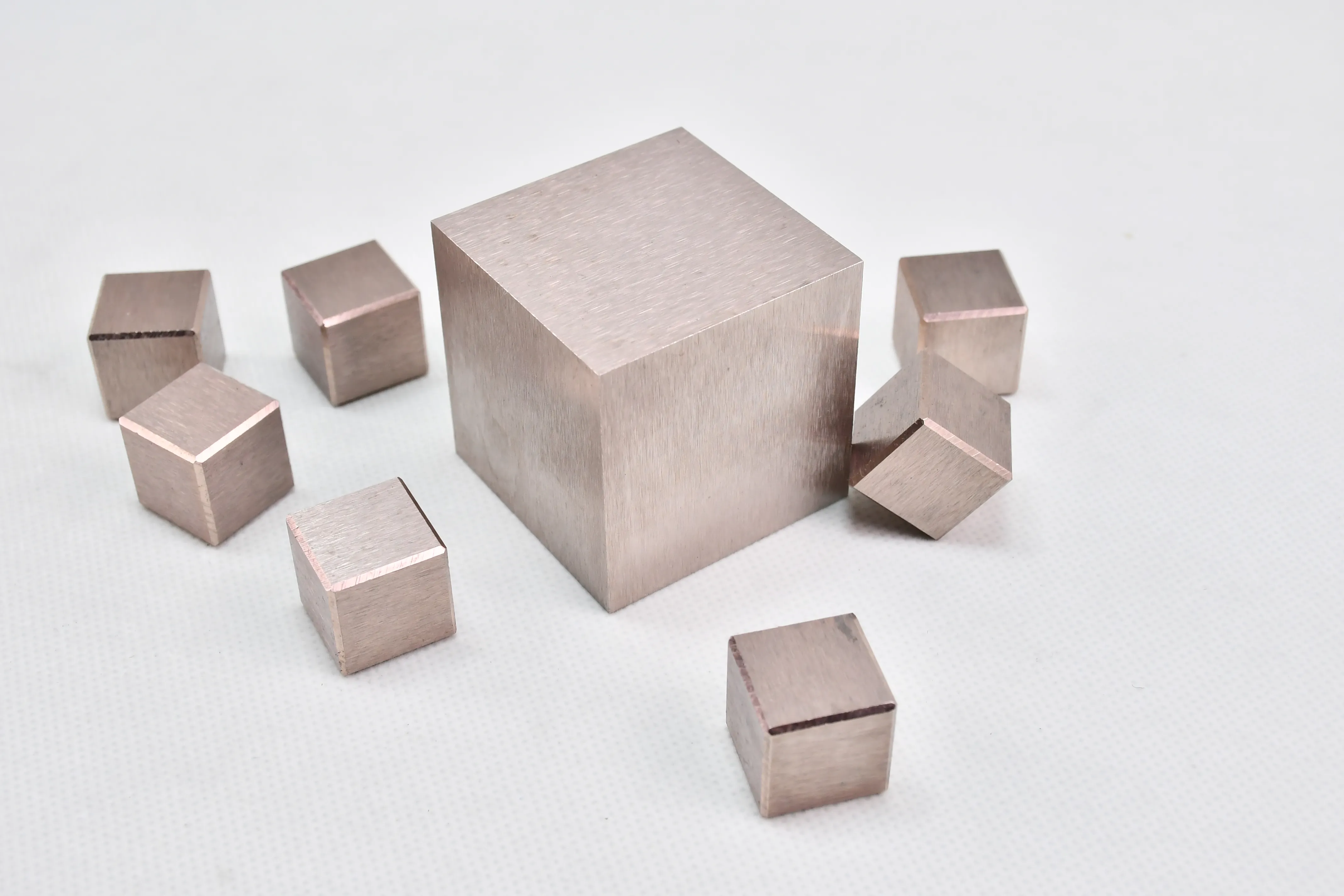

With the change in industrial technologies, tungsten heavy alloy supplier is still the material of choice for those parts that need both bulk and strength. Its high melting point and low plasticity make it an able performer during stress that is extreme and yet it remains precise in its dimensions. This is why engineers use it for making vibration absorbers, aircraft components, and kinetic energy penetrators. The coexistence of hardness and ductility guarantees a long operational lifetime, thus, making tungsten heavy alloy supplier a necessary input in high-performance engineering applications.

The use of tungsten heavy alloy supplier covers industries that require high strength-to-weight ratios and structural integrity. In aerospace engineering, it is found in counterweights for aircraft, balancing rotors, and control surfaces, where tolerance is important. The defense industry employs tungsten heavy alloy supplier in armor-piercing projectiles and for kinetic energy components, due to its high mass density and ability to withstand impact. Additionally, it serves oil drilling and heavy machinery applications for precision machining and stability under extreme vibration.

As an industry advances to increasingly perform better, tungsten heavy alloy supplier will see great depth of use in precision control systems, drones, and renewable power generation applications. Researchers are evolving sintering techniques that reduce material size and provide better designs based on fatigue criteria while being lightweight.

The life of tungsten heavy alloy supplier is consistent with care and maintenance. Do not drop or strike it against hard surfaces, as even minor impressions will impact the balance and performance of the tungsten heavy alloy supplier. Transport and store in tightly sealed containers to protect tungsten heavy alloy supplier from humidity and airborne contaminants.

tungsten heavy alloy supplier is a high-density material that is used in the aerospace, defense, and industrial sectors. Its strength, hardness, and wear resistance make it usable in environments where durability is needed and where weight distribution is compact. tungsten heavy alloy supplier offers excellent radiation shielding and thermal stability and continues to perform in high-temperature and high-stress situations.

Q: How is Tungsten heavy alloy used in oil and gas exploration? A: It serves as a key material for counterweights, drilling tools, and downhole equipment due to its density and wear resistance. Q: What maintenance practices help preserve Tungsten heavy alloy components? A: Regular cleaning, controlled storage, and protection from moisture help prevent oxidation and extend service life. Q: Why does Tungsten heavy alloy perform well in vibration control? A: Its density and internal damping capacity reduce oscillations in precision machinery and aerospace systems. Q: What machining techniques are best for Tungsten heavy alloy? A: CNC milling, grinding, and electrical discharge machining are commonly used for shaping Tungsten heavy alloy with precision. Q: How does Tungsten heavy alloy support environmental sustainability? A: It replaces toxic lead in many applications while offering durability and recyclability for eco-friendly production cycles.

The Tungsten heavy alloy handles extreme pressure and heat better than most metals I’ve used.

The tungsten jig feels incredibly durable — I’ve caught dozens of fish, and it still looks new.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are a machining parts supplier seeking tungsten heavy alloy rods for precision components. Kindly...

Do you provide OEM service for tungsten jig? We’d like to customize colors and hook types for our ...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved