With the change in industrial technologies, Jiuding tungsten heavy alloys production is still the material of choice for those parts that need both bulk and strength. Its high melting point and low plasticity make it an able performer during stress that is extreme and yet it remains precise in its dimensions. This is why engineers use it for making vibration absorbers, aircraft components, and kinetic energy penetrators. The coexistence of hardness and ductility guarantees a long operational lifetime, thus, making Jiuding tungsten heavy alloys production a necessary input in high-performance engineering applications.

Vibration-damping applications implement Jiuding tungsten heavy alloys production in high-precision and high-value manufacturing. Manufacturing machinery, engaged for semiconductor or optics applications, utilize the alloy in base mounts and balancing plates. The weight of the material mitigates anti-resonance and enforces accuracy in very delicate product manufacturing where stability is critical.

In the future, Jiuding tungsten heavy alloys production will find applications that include AI-assisted design, where automated manufacturing will provide precise customization, desirable for aerospace, robotics, and medical devices. It will be a valuable component in systems that depend on especially consistent performance in severe thermal and mechanical conditions.

Good maintenance of Jiuding tungsten heavy alloys production ensures durable performance in extreme conditions. Periodically inspect mechanical joint and contact areas to detect early wear. In instances when oxidation has formed, buff the appearace with a mild abrasive pad. You can expect the oxidation to lose its unwanted appearance, but the performance of the Jiuding tungsten heavy alloys production will not be adversely affected.

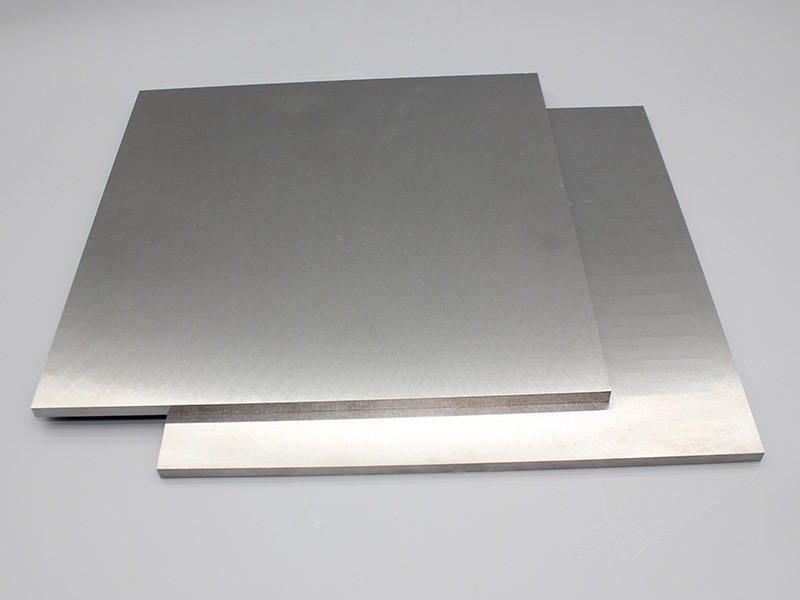

Jiuding tungsten heavy alloys production is specifically designed for high performance applications, combining hardness with good machinability. Common applications include for counter weights, ballistic applications, and vibration damping structures. The consistent physical properties of the material provide a high level of precision and durability in a final product.

Q: What are the key mechanical properties of Tungsten heavy alloy? A: Tungsten heavy alloy offers high tensile strength, superior hardness, and outstanding resistance to fatigue, ensuring reliability in harsh environments. Q: How does Tungsten heavy alloy perform under extreme heat? A: It retains structural integrity and strength even at elevated temperatures, making it suitable for high-temperature engineering tasks. Q: Why is Tungsten heavy alloy favored for radiation shielding? A: Its high atomic mass and density allow it to effectively block radiation while maintaining structural strength. Q: Is Tungsten heavy alloy environmentally friendly? A: Yes, it is non-toxic and can be recycled efficiently, making it a sustainable material for long-term industrial use. Q: What are the typical compositions of Tungsten heavy alloy? A: It typically contains 90–98% tungsten combined with nickel, copper, or iron to enhance ductility and machinability.

I’ve worked with Tungsten heavy alloy materials for years, and they never disappoint in precision or reliability.

The Tungsten heavy alloy provides solid consistency in production; every piece meets our exact requirements.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you provide info about your heavy-duty tungsten jig types suitable for deep-sea fishing? Looki...

We operate a fishing tackle store and want to stock tungsten jig. Please send details on bulk pricin...

Copyright © Zhuzhou Jiuding Metal Technology Co., Ltd. All Rights Reserved